Cliff Notes:

Port only swap: +23 / +17

another 3/4 lb of boost on the high end

No added timing - 22* was the most it would take, but approx 2.5% more fuel.

It had just stopped raining before the final pull.

-------------------------------------------------------------------------------------

Setup:

Ok, baseline is in - 612 / 580. We're down about 40 / 50 from the exhaust swap in March. Of course, it was 40 degrees and dry then - 83-91 degrees and humid/drizzling today. However, the power curves are pretty similar so I will blame this on the weather, a hot car (and a conservative street tune!). So, ladies and gentlemen, THIS is why we do baselines!

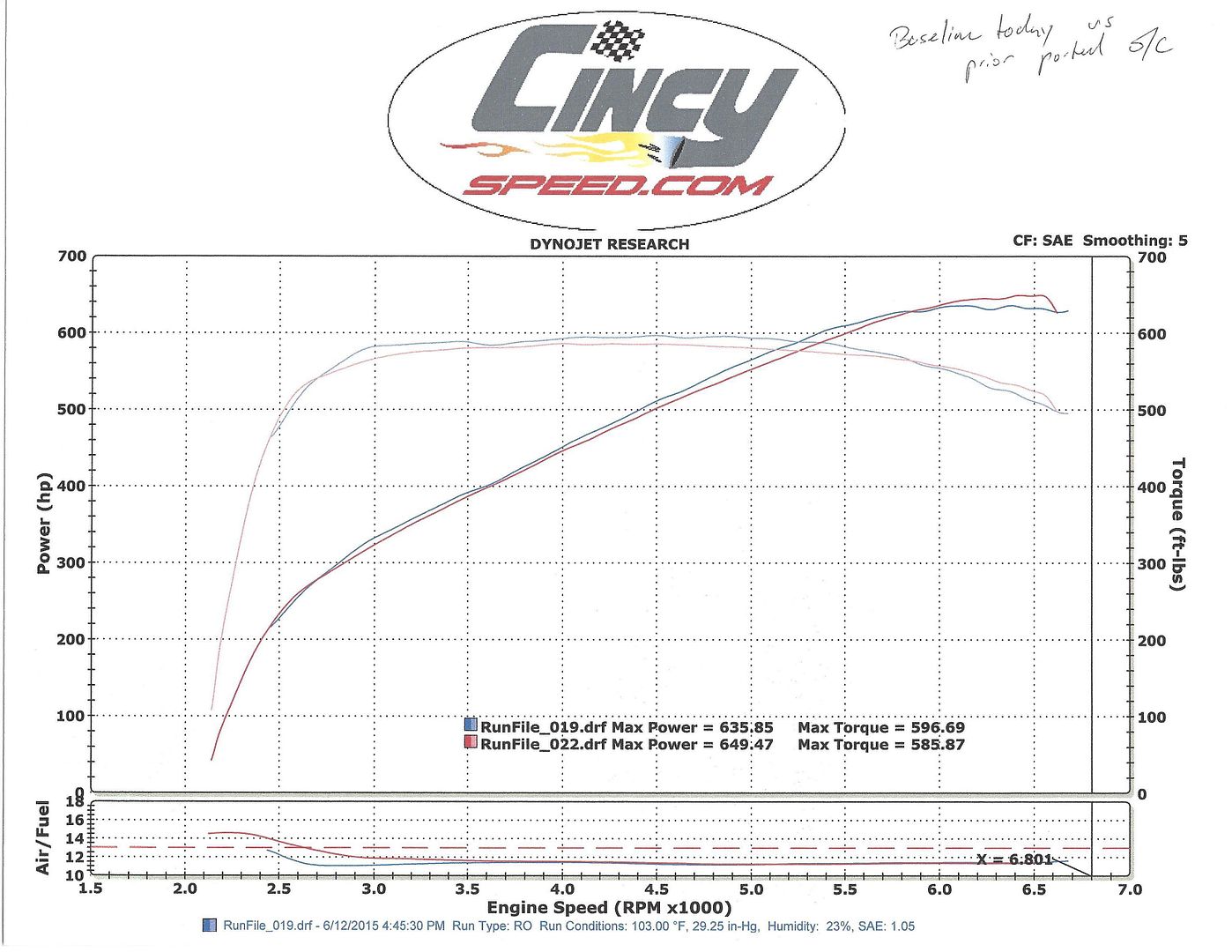

Today's baseline (red line) vs best pull from 03-19-15. AFR just about the same at 11.25-11.45 but 1-2 degrees less timing from March:

![Image]()

I am sweating as I type this while sitting in an air-conditioned shop. Yes, it's hot and a bad day for glory numbers! I am logging every dyno pull to check for KR or other issues and will post those up later. I completed 4 baseline pulls to make sure fuel and timing were in-line, with NO timing changes inbetween the Before/After runs. Approximately 2.5% fuel was added in total, with AFR of 11.5.

Final before / after:

![Image]()

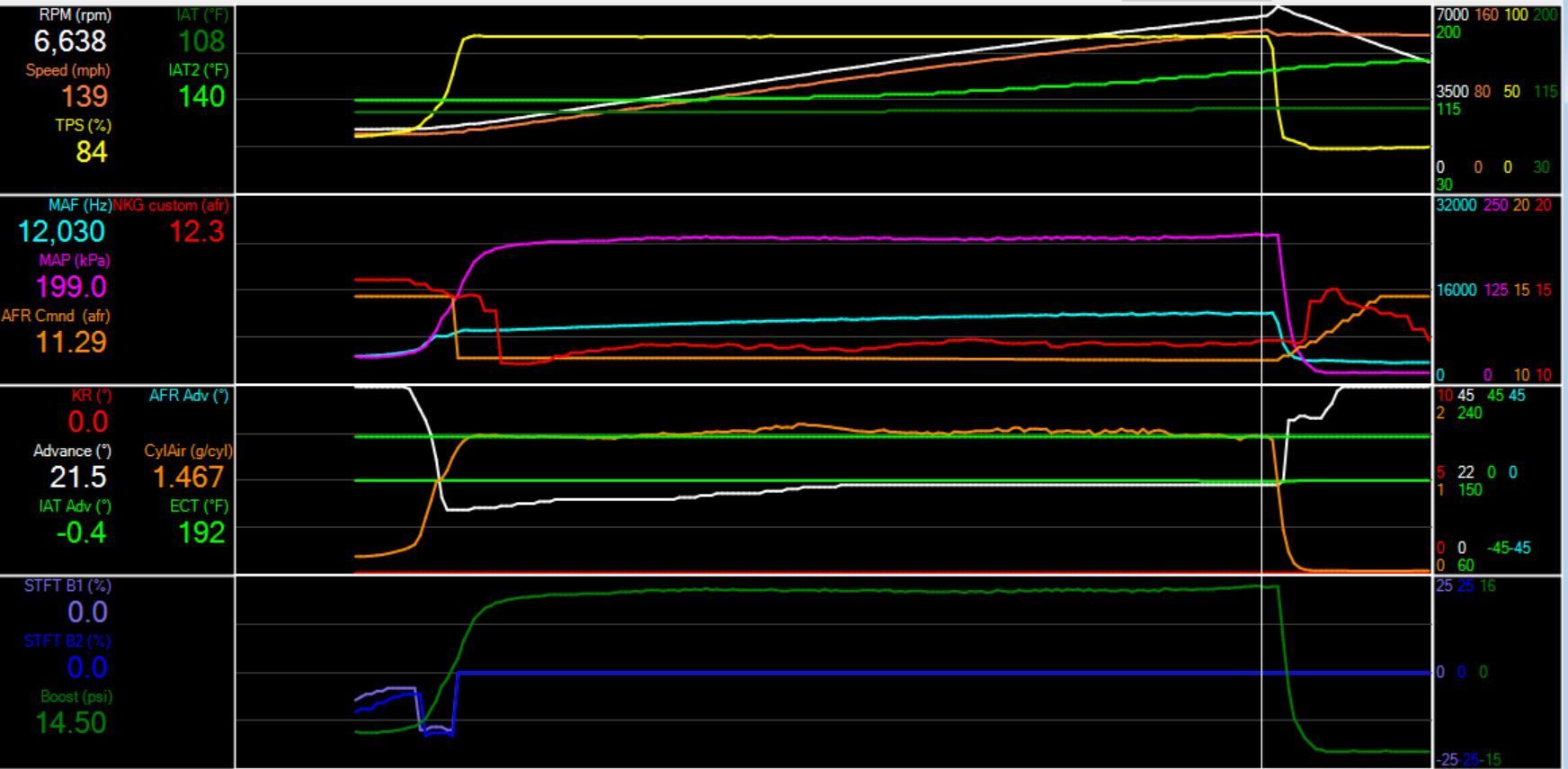

Datalogs of the Baseline Run (NOTE: Wideband is not accurate!)

![Image]()

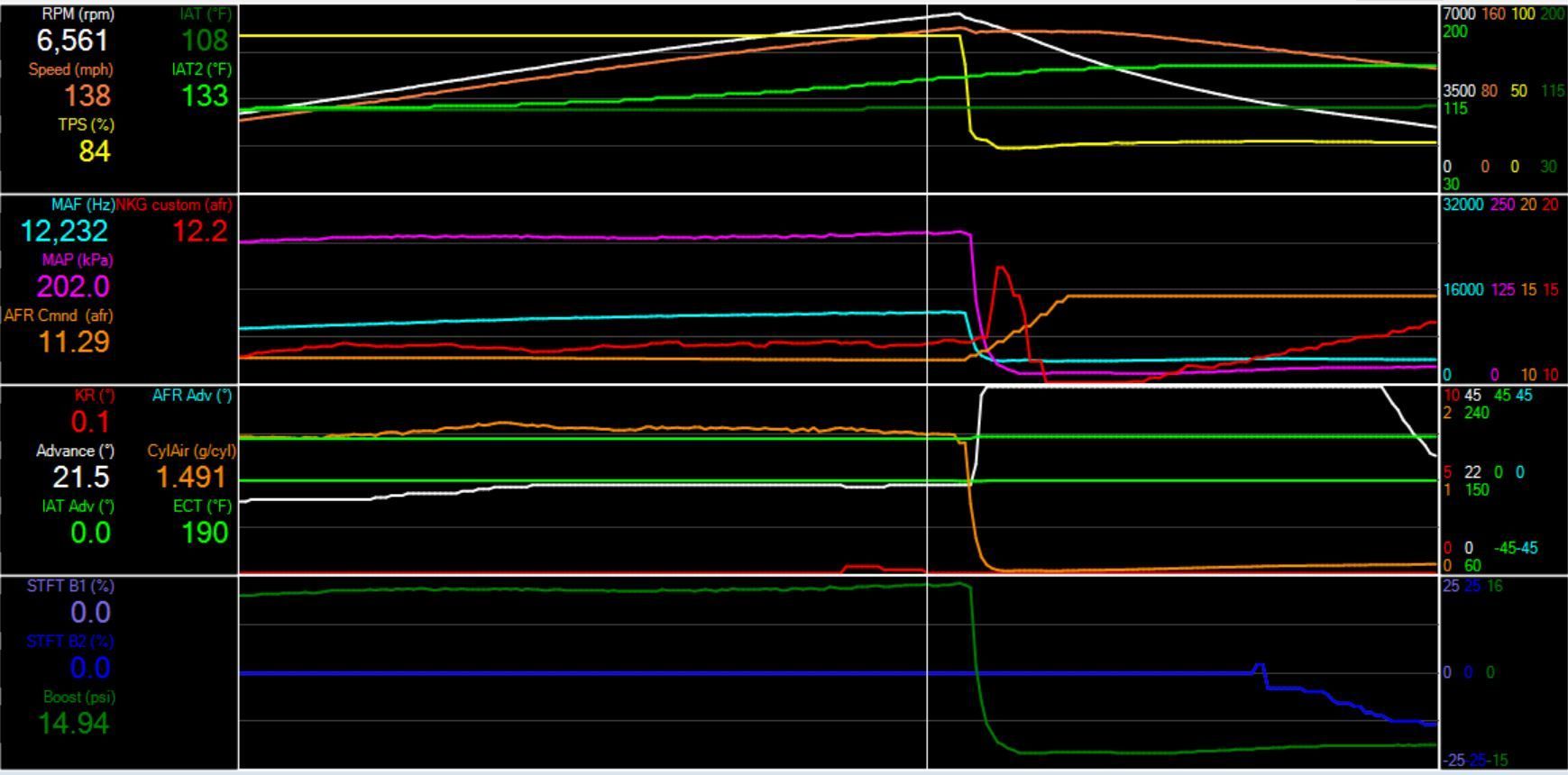

Datalog of the AFTER Run. Timing is unchanged, however I am pulling more boost and get a touch of KR at the top of the AFTER pull (it did not appear to affect peak numbers much). Again, very hot, very humid and not ideal for a blower-car glory run:

![Image]()

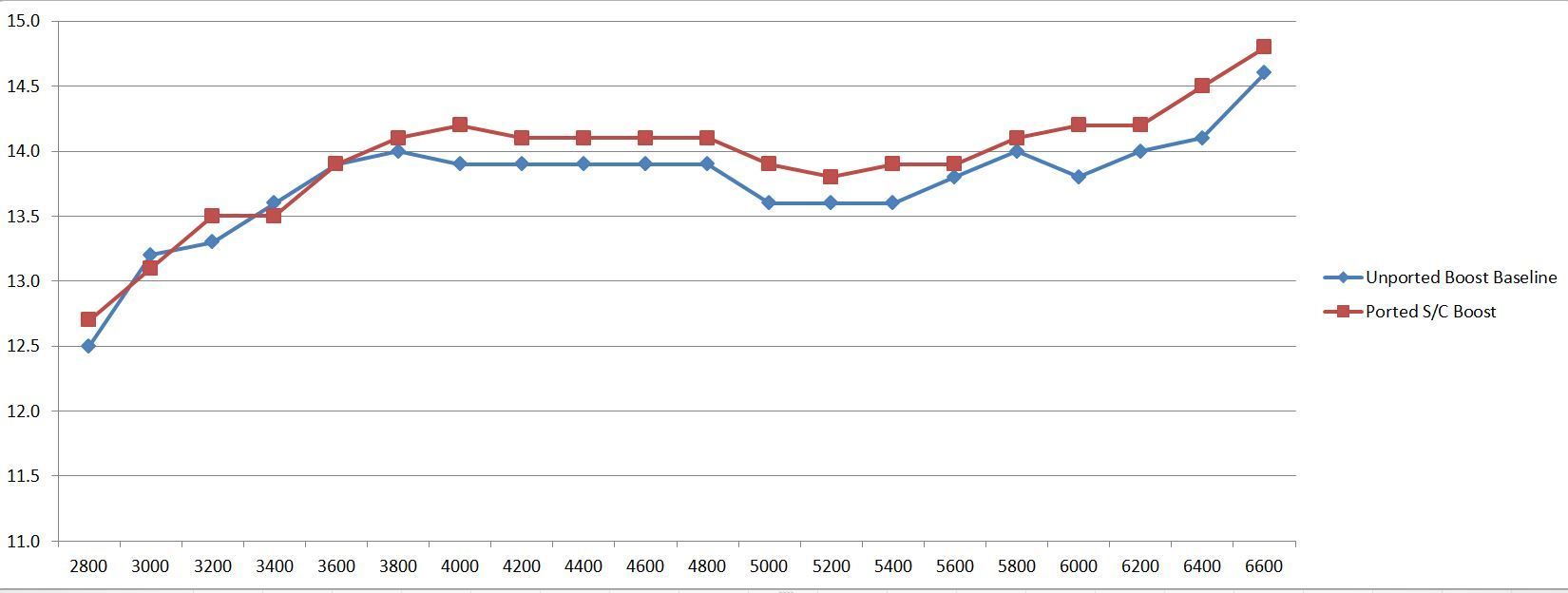

Boost Curve Delta:

![Image]()

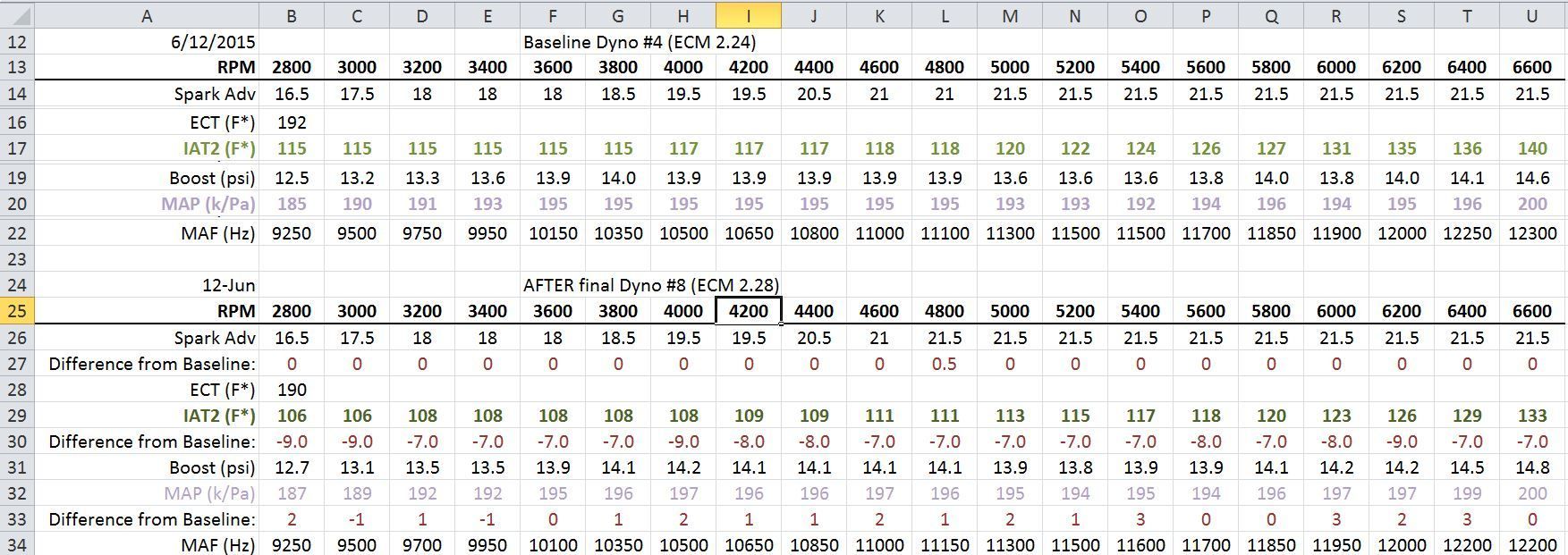

Spreadsheet Deltas:

![Image]()

Thoughts:

* I think ~25/20 is a realistic expectation for typical ported blower gains. Clearly, the 90+ heat and humidity can crush your dyno-dreams on a blower car! * Also, My S/C was over-ported in the intake area relative to the stock heads intake runners, possibly contributing to a small amount of power loss - how much is debatable. However, every ported S/C I've seen does this so I mention it only as an FYI to Brett and others to be sure to clarify what heads you're intending to use the S/C on.

* Boost is up across the board, which implies gains from the snout and transition porting. I think the ideal setup is how my S/C is ported pre-rotor, with only smoothing to the post-rotor intake runner area without hogging it out. I expect boost (pre-rotor S/C efficiency) would increase further if I had a 90mm or 102mm throttle body and appropriate CAI.

* The greatest gains were 6K and up - the baseline pull definitely flattens off, whereas the AFTER run has a more natural curve to it in spite of 0.4* KR at 6200 RPM. IMHO, this suggests the unported casting is starting to struggle to support enough airflow at the higher end of the curve - whereas the ported unit has less restriction and more efficiency.

* I baselined with a conservative street-orientated tune in timing and desired AFR (11.5 or less). Peak power numbers could be increased with a leaner AFR; however that was not my goal. Dynos are always optimistic without the full load, heat soak and dynamics of pulling hard on the street.

* Although there were a few miscommunications between Jokerz and I, I think the quality of his porting is as good as anyone and he strikes me as an honest, honorable guy to work with. He went out of his way to fix those little things that pop up when you're working on a timeline, at his cost and without argument. I am really impressed with his character and dedication to making a name for himself here on the board.

Recommendations:

* Make sure your porter knows if you're running stock LSA heads, ported LSA heads or aftermarket.

* Colder, more dense air in the spring / fall could theoretically support up to a 40 RWHP gain IMHO given the boost, timing and power levels. I might dyno again if cooler weather comes in soon, just to see what happens!

* After handling a competitor's product last year and posting photos of the porting, I prefer Jokerz' product and have the highest level of trust in his competency. My opinion is that I will buy his services again; the competitor's I would not.

* I personally suspect there will be little to no reproducible power difference between the various S/C porting options - I think the bread and butter of opening these things up is in the snout and case transition; everything else is for looks. Simply put, I personally would recommend Brett / Jokerz over any presently-available supercharger porting service without question, even though some competitors have more aggressive porting in some less-critical areas.

--------------------------- UPDATE -----------------------------------

ETA: A second ported supercharger comparison was completed 08/28/15 to test a different snout and runner configuration. That variance only netted +4-5 RWHP with no change in peak torque. However, I wanted to update this post to show that a re-dyno of the same original Jokerz ported supercharger picked up another 15 RWHP when dynoed in more forgiving dry, 70* weather!

This is the overlay of the final 6/12/2015 dyno run with Jokerz ported supercharger (90+ degree temps while raining) vs the SAME supercharger - with NO hardware changes other than some fueling and timing tweaks - on the SAME dyno 6 weeks later on 08/28/2015 (70 degree temps and dry):

![Image]()

Delta: +14 RWHP due to temperature changes.

NOTE: Timing was pulled on the street, which is likely why peak torque is actually DOWN in the second, cooler run. But I have to keep it safe for my daily driving, so no glory runs here. Sorry.

Port only swap: +23 / +17

another 3/4 lb of boost on the high end

No added timing - 22* was the most it would take, but approx 2.5% more fuel.

It had just stopped raining before the final pull.

-------------------------------------------------------------------------------------

Setup:

Ok, baseline is in - 612 / 580. We're down about 40 / 50 from the exhaust swap in March. Of course, it was 40 degrees and dry then - 83-91 degrees and humid/drizzling today. However, the power curves are pretty similar so I will blame this on the weather, a hot car (and a conservative street tune!). So, ladies and gentlemen, THIS is why we do baselines!

Today's baseline (red line) vs best pull from 03-19-15. AFR just about the same at 11.25-11.45 but 1-2 degrees less timing from March:

I am sweating as I type this while sitting in an air-conditioned shop. Yes, it's hot and a bad day for glory numbers! I am logging every dyno pull to check for KR or other issues and will post those up later. I completed 4 baseline pulls to make sure fuel and timing were in-line, with NO timing changes inbetween the Before/After runs. Approximately 2.5% fuel was added in total, with AFR of 11.5.

Final before / after:

Datalogs of the Baseline Run (NOTE: Wideband is not accurate!)

Datalog of the AFTER Run. Timing is unchanged, however I am pulling more boost and get a touch of KR at the top of the AFTER pull (it did not appear to affect peak numbers much). Again, very hot, very humid and not ideal for a blower-car glory run:

Boost Curve Delta:

Spreadsheet Deltas:

Thoughts:

* I think ~25/20 is a realistic expectation for typical ported blower gains. Clearly, the 90+ heat and humidity can crush your dyno-dreams on a blower car! * Also, My S/C was over-ported in the intake area relative to the stock heads intake runners, possibly contributing to a small amount of power loss - how much is debatable. However, every ported S/C I've seen does this so I mention it only as an FYI to Brett and others to be sure to clarify what heads you're intending to use the S/C on.

* Boost is up across the board, which implies gains from the snout and transition porting. I think the ideal setup is how my S/C is ported pre-rotor, with only smoothing to the post-rotor intake runner area without hogging it out. I expect boost (pre-rotor S/C efficiency) would increase further if I had a 90mm or 102mm throttle body and appropriate CAI.

* The greatest gains were 6K and up - the baseline pull definitely flattens off, whereas the AFTER run has a more natural curve to it in spite of 0.4* KR at 6200 RPM. IMHO, this suggests the unported casting is starting to struggle to support enough airflow at the higher end of the curve - whereas the ported unit has less restriction and more efficiency.

* I baselined with a conservative street-orientated tune in timing and desired AFR (11.5 or less). Peak power numbers could be increased with a leaner AFR; however that was not my goal. Dynos are always optimistic without the full load, heat soak and dynamics of pulling hard on the street.

* Although there were a few miscommunications between Jokerz and I, I think the quality of his porting is as good as anyone and he strikes me as an honest, honorable guy to work with. He went out of his way to fix those little things that pop up when you're working on a timeline, at his cost and without argument. I am really impressed with his character and dedication to making a name for himself here on the board.

Recommendations:

* Make sure your porter knows if you're running stock LSA heads, ported LSA heads or aftermarket.

* Colder, more dense air in the spring / fall could theoretically support up to a 40 RWHP gain IMHO given the boost, timing and power levels. I might dyno again if cooler weather comes in soon, just to see what happens!

* After handling a competitor's product last year and posting photos of the porting, I prefer Jokerz' product and have the highest level of trust in his competency. My opinion is that I will buy his services again; the competitor's I would not.

* I personally suspect there will be little to no reproducible power difference between the various S/C porting options - I think the bread and butter of opening these things up is in the snout and case transition; everything else is for looks. Simply put, I personally would recommend Brett / Jokerz over any presently-available supercharger porting service without question, even though some competitors have more aggressive porting in some less-critical areas.

--------------------------- UPDATE -----------------------------------

ETA: A second ported supercharger comparison was completed 08/28/15 to test a different snout and runner configuration. That variance only netted +4-5 RWHP with no change in peak torque. However, I wanted to update this post to show that a re-dyno of the same original Jokerz ported supercharger picked up another 15 RWHP when dynoed in more forgiving dry, 70* weather!

This is the overlay of the final 6/12/2015 dyno run with Jokerz ported supercharger (90+ degree temps while raining) vs the SAME supercharger - with NO hardware changes other than some fueling and timing tweaks - on the SAME dyno 6 weeks later on 08/28/2015 (70 degree temps and dry):

Delta: +14 RWHP due to temperature changes.

NOTE: Timing was pulled on the street, which is likely why peak torque is actually DOWN in the second, cooler run. But I have to keep it safe for my daily driving, so no glory runs here. Sorry.